2020

For more than a year, I have not written any more. Unfortunately, this does not mean that we have awakened from our nightmare. Rather, so many unbelievable and unpleasant things have happened in the meantime that I didn’t even want to think about it any longer.

But now that we have been contacted again by other affected people and asked for help, we think it is time to continue writing. Moreover, we have received a lot of encouraging feedback and have made new friends out of this unfortunate situation.

What happened in 2020

The main problem: The too weak engine.

In part 4 of our never ending story we had already mentioned that the test drives were without success. The repeated test run on November 21 only confirmed that of the 50 to 60 kW of engine power that the engine could theoretically have produced, only about 30 kW was delivered. This 30 kW was all that was achieved.

After this last test drive, even Kees Cornelissen came to the conclusion that this was neither the agreed nor the required drive power.

Finally. But. . .

Wir haben zusammen eine 60 kW Motor gekauft und wir haben bis heute die 60 kW nicht gekriegt. Ende. Und die Motor geht auf meine Rechnung nicht raus. Weil Bellemarine muss uns zuerst 60 kW mit 1850 Umdrehungen liefern. Kees Cornelissen, 21.11. 2019

He urged us to take joint action against the engine supplier Bellemarine. Bellemarine had in his opinion not delivered the power he had ordered. He ignored the fact that he himself had not installed the double engine of 100 kW that we had ordered, but simply a double engine of 50 kW. With a 75 ton ship, this is like trying to mix concrete with a hand mixer.

Even though Cornelissen admits that the engine does not deliver the power, he still asks us for 78,874 euros more, for the electric drive that he had installed under our protest .

Not to mention the 108'529 euros for additional interior work of which he cannot explain what it consisted of. We had of course paid for the interior work that we had actually ordered.

So that's a total of 187'403 euros that Cornelissen wants more of.

Our lawyer recommended that we take the boat away from Kees Cornelissen Shipyards International/Euroship Services and have the electrical components, which were too weak, replaced by a reputable shipyard.

Since Kees Cornelissen refused to release our boat voluntarily, we needed a court decision for this as well. We spare here the detailed report about the court hearing, which took place on December 17, 2019. The bottom line of the January 8, 2020 ruling was that Kees Cornelissen had to deliver our boat and we had to pay him the final installment for ordered options that we had accepted and that the court had upheld, minus the fines owed by the shipyard for the late delivery. What a relief.

We set this pick-up date for January 14, 2020. Roland collected our trade-in boat, the Adnobis from the broker in Sleeuwijk and we organized as a precaution a tugboat that would be waiting for us on the Waal, i.e. after the St. Andries lock, we already knew that the engines would not be able to cope with the countercurrent on the Dutch part of the Rhine.

In the meantime, through the mediation of our Canadian fellow sufferers, John and Rosemary Teed, we had met a very nice young man who was helpful to us in all matters. Ramon Noy ran the boat service in Beneeden-Leeuwen until the end of 2020 and offered us to lie alongside his boat for the time being until we knew exactly what would happen next.

We also leave out the more than unpleasant boat handover by Cornelissen on January 14. Joris Klompé had organized as a precaution to place an arrest on the trade-in boat, our Adnobis. Our contracting party, Kees Cornelissen Shipyard International BV has no assets. So if we wanted financial compensation for the non-functional components of the CaRo, we needed security.

The bailiff was standing by and we gave her the door handle in the hand as we walked out of the shipyard office.

As was to be expected, nothing was explained to us. We were given two of the three keys to the CaRo, which was handed over without a registration number or name and without ES_TRIN (in the Netherlands Certificaat van Onderzoek), though with an invalid CE certificate, and a «go figure it out". Roland headed together with Ramon and Guido Beekmann, our expert on the Maas in the direction of the Waal.

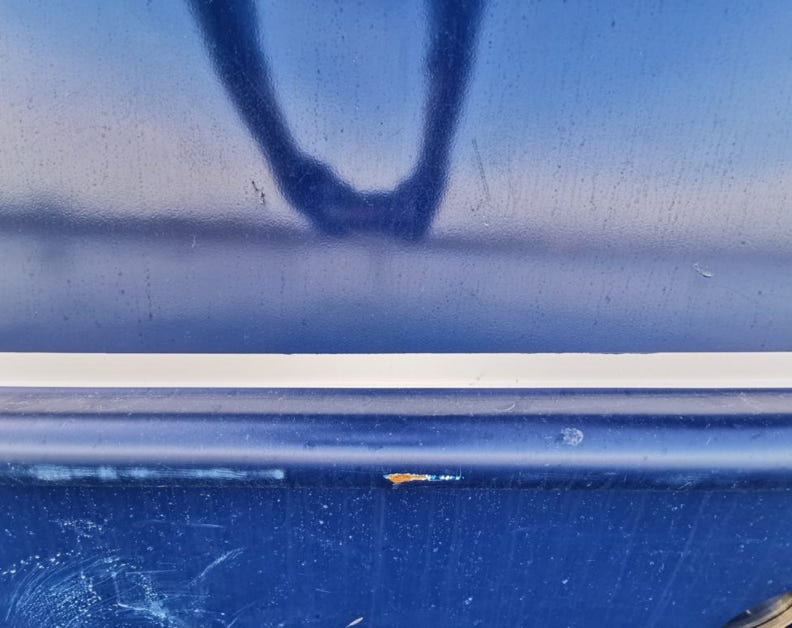

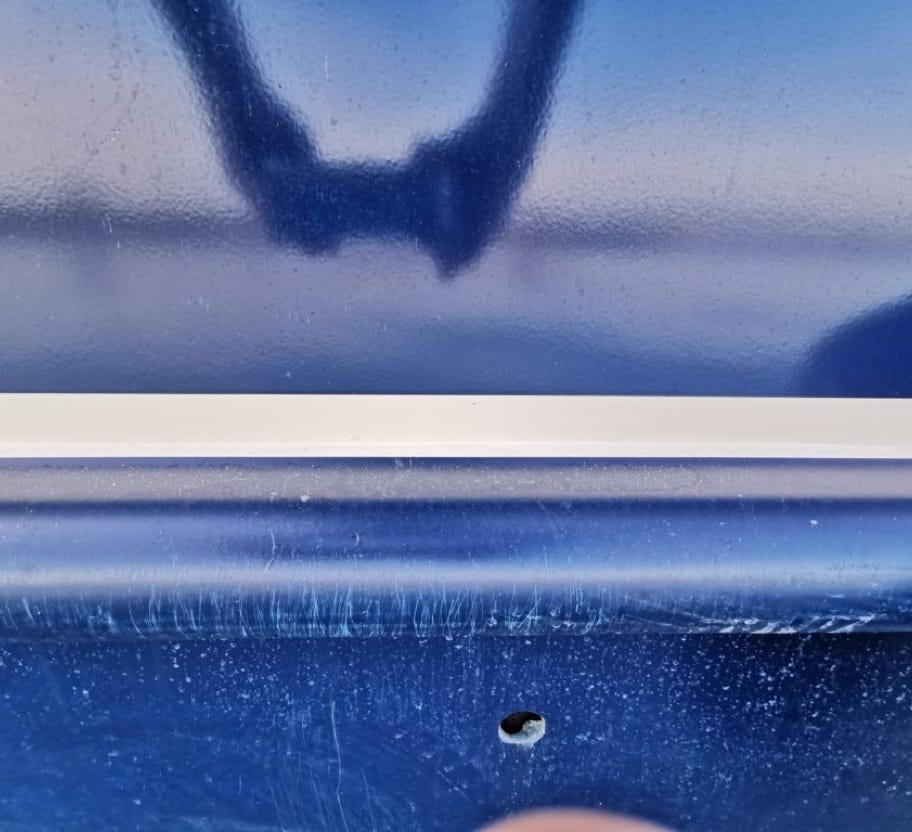

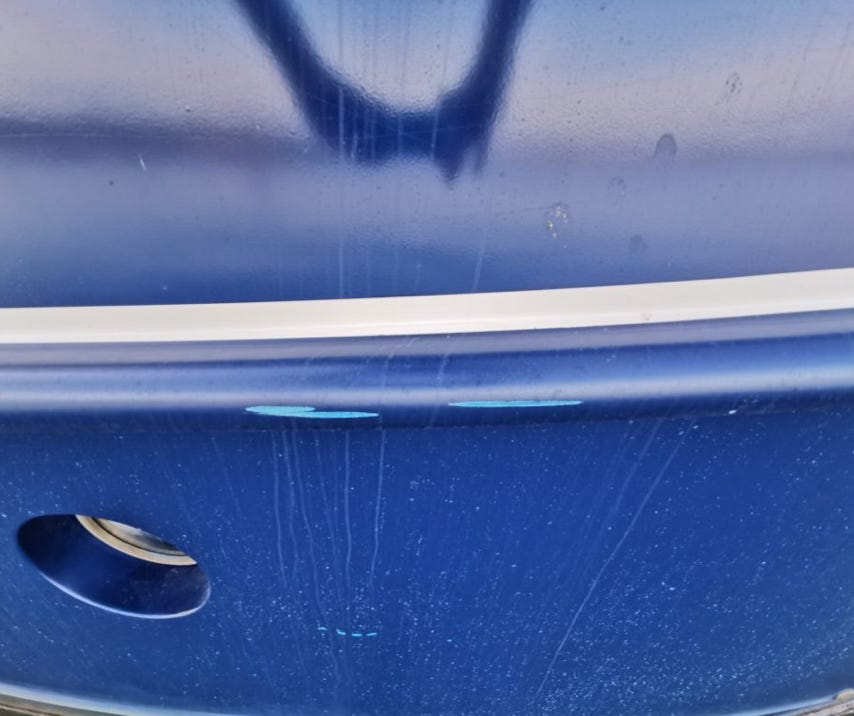

There lies the Caro. Nameless with a dent in the bow and scratched sideboards in front of the St. Andries lock.

In the St. Andries lock the engine failed for the first time and it took a while until we could sail out of the lock. Right after the lock our Dutch captain, Uge Deen with his wife Lien were waiting for us on the tow boat and brought us safely and in one piece to Beneden Leeuwen.

After the lock, the tugboat was waiting for us.

Beneden Leeuwen

There we were, trying to figure out what was wrong with this brand new boat that had been delivered to us with a dent in the bow and terribly scratched sides. Cornelissen later said, according to court records, that these were "normal usage marks."

Normal use marks on a new boat when it was picked up.

Today we almost laugh about it. But in January 2020, when we were sitting there freezing miserably, it wasn't funny at all.

We will especially remember when we connected the shore power and the lights went out in the whole neighborhood. Over the next few weeks, the entire misery gradually came to light.

If we wanted to heat, the generator had to run. If the shore power was connected at the same time as the generator, the toilet pumps and the refrigerator no longer worked. This means that either shore power 440 V had to be plugged in or only the generator had to run. Depending on the one or the other worked. Or maybe not.

It was cold

The Marifoon (the radio) was not programmed.

Instead of the AIS A required for this size ship, Cornelissen had installed an AIS B. To get at least a provisional ES-TRIN (CvO) permit, an AIS A had to be installed first. The incorrectly installed AIS B was not taken back by Kees Cornelissen Shipyard or the electrical supplier of his trust, Frank Hooymans. At least not for the price we had paid.

We could not get our dishwasher to work because it was so dented at the top that it was hanging down and the water nozzle was caught in the silverware basket. It was as if someone had stood on it. The machine had not been bolted down.

The CE certificate issued was invalid. Cornelissen had no authority to self-certify a boat equipped with electric motors. He did it anyway.

Without CE, however, one does not receive an ES-TRIN (CvO). We have not received either certificate until today, February 26, 2021.

The sliding side doors to the outside had been glued poorly or not at all and had large gaps. The door locks were screwed up and the doors could not be locked. In addition, we had received only two of the three keys supplied for the boat. Cornelissen, according to court records, said of the gaps "They wanted ventilation for the dogs . . .».

The provided manual referred to equipment handbooks that were not on the boat.In exchange, it did not mention the potentially overflowing shower pump tank, which had been mounted inaccessibly under the floorboards.

The engine room lacked ventilation. This would have been essential for CE certification.

The 230 V shore connection did not work. As soon as the connection received power, the new electrician discovered that the cable went to the switch box, but not a single cable away from it.

The heater was leaking. The regulating valve that allows hot water to be produced when the heater is not running was missing. Especially in midsummer this is a very pleasant option, if you do not want to take a cold shower and not want to heat. According to the plumber, the regulating valve is always supplied automatically with this heater.

The bow cabin could not be warmed up to more than 15 degrees even in sub-zero temperatures. The heating was connected to only one circuit. That meant 23 degrees upstairs, 15 downstairs. Period.

The inverter was defective.

The battery charge indicator was missing. So we had no idea if the batteries could still supply power or not.

The boat was poorly insulated. Condensation was running down the walls in the bow.

The electrical outlets in the salon only worked when the lights were on at the same time. There were no outlets in the guest bathroom.

A wifi was ordered by us and charged by Cornelissen. It was just unfortunately not installed.

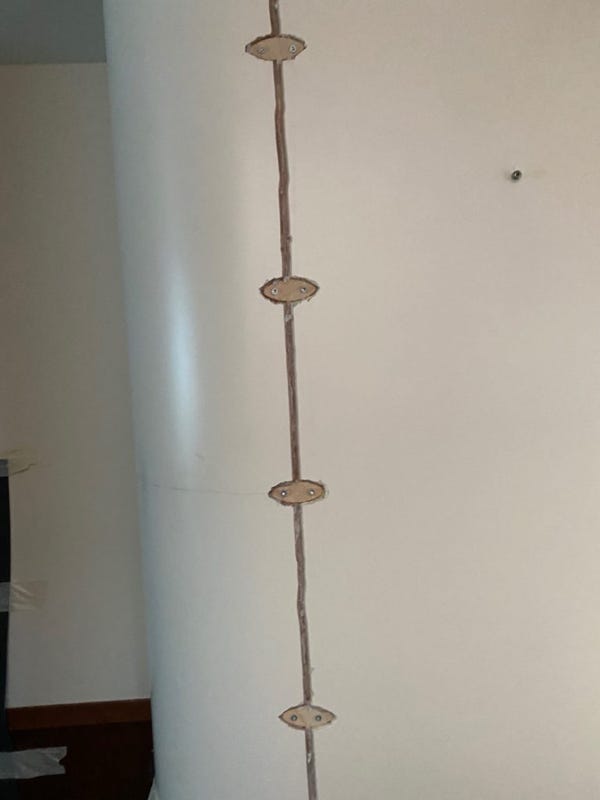

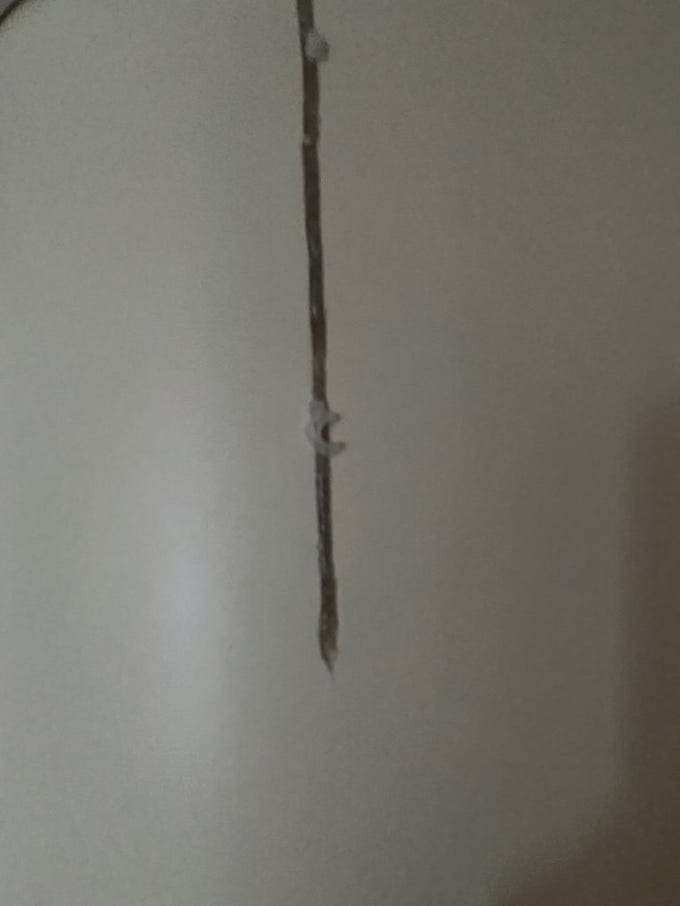

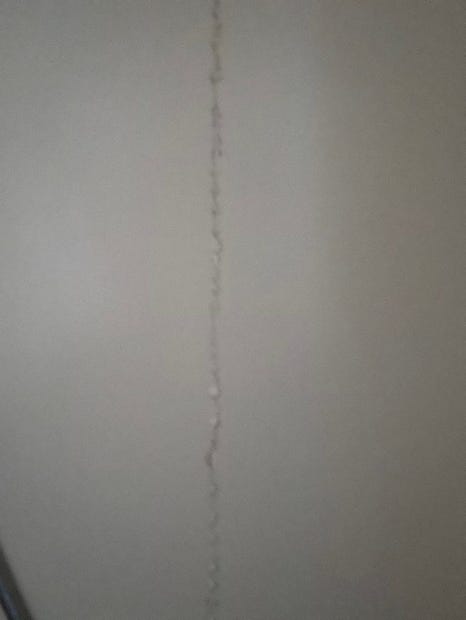

The wood of the interior was already cracked in many places. Among other things, the wall between the corridor and the shower. The repair was extensive.

Massive cracks in the walls

Oops. The door frame fell down.

In the rear shower, the heat exchanger had hot and cold water mixed up. So you were either boiled or showered off ice cold.

The windows on the upper deck were puttied only on the three directly visible sides. The putty joints are missing on the bottom.

The glass countertop in the kitchen was delivered with dirt straps that could not be removed. Somewhat later it was completely cracked due to excessive tension.

Dirty and burst due to a too high tension.The price of the countertop was about 7’000 euros.

The single glazing of the portholes and escape hatches draws condensation that drips onto the veneered mahogany furniture below. The fournier has since come loose. At the same time, Cornelissen claimed before the order that they would use only solid wood as a matter of principle. He made fun of Linssen Yachts' cheap veneer work.

The closing mechanism is missing on several cabinet doors.

The toilet doors have a lock. However, this was installed at such an angle that the doors still cannot be locked.

The ballast was arranged in such a way that the center of gravity was in the stern and, when the ship was underway, the floating platform was completely submerged. The ballast consisted on the one hand of fully glued lead plates and on the other hand of a metal/concrete granulate that was loosely poured into the bilge. Neither was optimal.

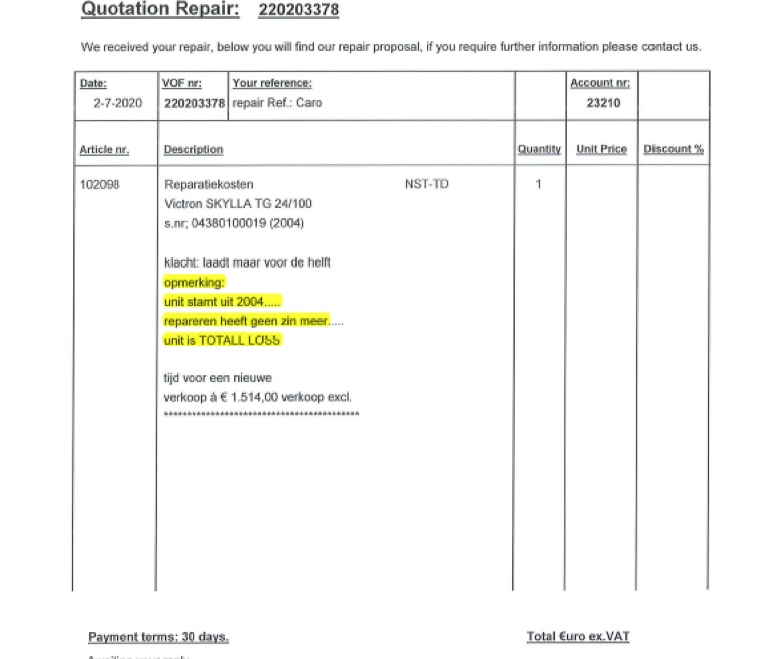

When the battery charger completely gave up, we tried to get warranty service from the supplier. He just laughed and confirmed that the charger was from 2004 and that he could no longer give a warranty on it. So a total loss.

The anchor was too light for the weight of the boat and not operable. The anchor chain was too short. All things that are mandatory for a CvO. The windlass was installed too close to the side of the boat and it could not be turned. Later the winch was dismantled, which did not solve the problem.

Deck wash system installed by Tinnemans Custom Built Yachts, Maasbracht.

The deck washing system that was installed by Kees Cornelissen Shipyards and Euroship Services Heerewaarden. This was all the water that came out. Roland was appalled when he started it for the first time.

The list is endless. We can't even list everything here. Fortunately, our expert had already included all identifiable defects in his expert reports prepared since September 2019. Why the shipyard had not corrected these defects by January 2020, we do not know.

Roland was able to repair some things himself - despite the help of the Wuffs.

So we lay in Beneeden Leeuwen and went in search of a shipbuilder who knows how to build boats. We visited some shipyards and some shipyards visited us.

We were invited by Ramon for a fish dinner.

In February, we decided to take our CaRo, now properly registered, to Maasbracht to Tinnemans Custom Built Yachts. While Roland set off with our captain Uge Deen and his wife Lien, I drove home to Switzerland with the 5 Wuffs.

Tinnemans set to work with much effort and we waited for things to happen during the first Corona wave.

The main work consisted of replacing the electric drive with a conventional diesel drive. The situation was complicated by the fact that environmental regulations for diesel engines had become stricter, but there were still almost no engines already certified. The diesel engine Cornelissen originally offered, moreover, was already no longer compliant with EU requirements when he offered it.

Since neither Kees Cornelissen Shipyard International nor its Euroship Services, which was entrusted, offered a hand to replace a demonstrably non-functioning electric drive with a functioning one - as it should be under warranty - we were forced to pay Tinnemans in advance. It was also quite clear to us that we would only get this money back from Cornelissen via a court of law. On the advice of our lawyer Joris Klompé, Jan Tinnemans brought all the electrical components back to Heerewaarden.

On the way to Maasbracht, our experienced captain Uge noticed that the rudder only had a range of 30°. This is too little to maneuver a ship of this size. In addition, the rudder arm got caught in the insulation when the ship was at maximum rudder deflection. The rudder was blocked, the boat unable to maneuver. The crew experienced a real panic situation that could have been very dangerous. The pressure was so great that the entire rudder shaft was distorted.

So Tinnemans fixed the propeller according to regulations, extended the rudder blade forward and added a so-called fishtail aft, which improved maneuverability. The same problem, by the way, was encountered by the Jenal also built by Cornelissen.

Likewise, the problem with the distance from the ship's side to the rudder shaft was fixed. The rudder arm can no longer hook. However, the rudder deflection of only 30° is still not good.

Roland had already complained about the distance from the propeller to the rudder blade to Cornelissen on September 17, 2020. Cornelissen only said that there was nothing wrong with the distance. As soon as the Caro was on the dry dock, Tinnemans noticed that the propeller was poorly fastened.

On previous ships built by Cornelissen (Aslaug, Forty Roses III), the propeller sank during the voyage into the depths of the respective fairway. Obviously, this could have happened to us. Life-threatening when it happens on a stream much frequented by cargo ships.

Uge Deen: «de spie in de schroefas is het een grote schande»

Tinnemans: «De spie was veel te klijn.»

In June 2020 we traveled back to the Netherlands and at the end of July 2020 we were able to take delivery of our Caro.

Tinnemans drew our attention to the fact that the considerable amount of water in the bilge, which we had been carrying with us since we took over the Caro, had still not dried. So we pondered where this water might be coming from and a nasty suspicion arose. Was the PVC fresh water tank leaking, which inflated so roundly every time it was filled that the guest bed became a rocking bed?

We asked Tankgigant, who had supplied the tank to Cornelissen, for his professional opinion. However, the employee only shook his head. Their tanks were to be mounted completely underneath. Our tank was lying on the frames. In addition, it would not withstand the pressure from the two additional vertical tanks behind it. Tankgigant denied any liability. However, also because the installed PVC tank no longer met today's standards.

We had to digest that first and think calmly about how to proceed.

Tinnemans had anyway now company vacations and so we decided to steer our boat for the first time with a safer feeling in the direction of Plasmolen and to familiarize ourselves with the now diesel-powered driving characteristics. It was high summer and we departed with the Wuffs cheerfully.

More or less uneventfully we reached Asselt, where we moored in the middle of free nature on a small quarry pond. It had no road and no people all around and we enjoyed peace and dog walks.

So we lay on August 10 in sweltering heat together with the Wuffs on the shady back deck and enjoyed sweet idleness. Until I heard a voice politely asking if I was Mevrouw Stirnemann. I opened my eyes. Standing in front of me, albeit slightly sweaty, was a dapper young man in a white shirt. Completely puzzled, I asked him where he was from and why he knew my name. He was the bailiff and yes, he had indeed walked from far away, after he had first been sent in the completely wrong direction. Hmmh? He didn't want to drink anything but just hand me the papers to put an order of arrest on our boat.

Wilhelm Busch would have said, "This was the first prank. . ."

Cornelissen's assertion:

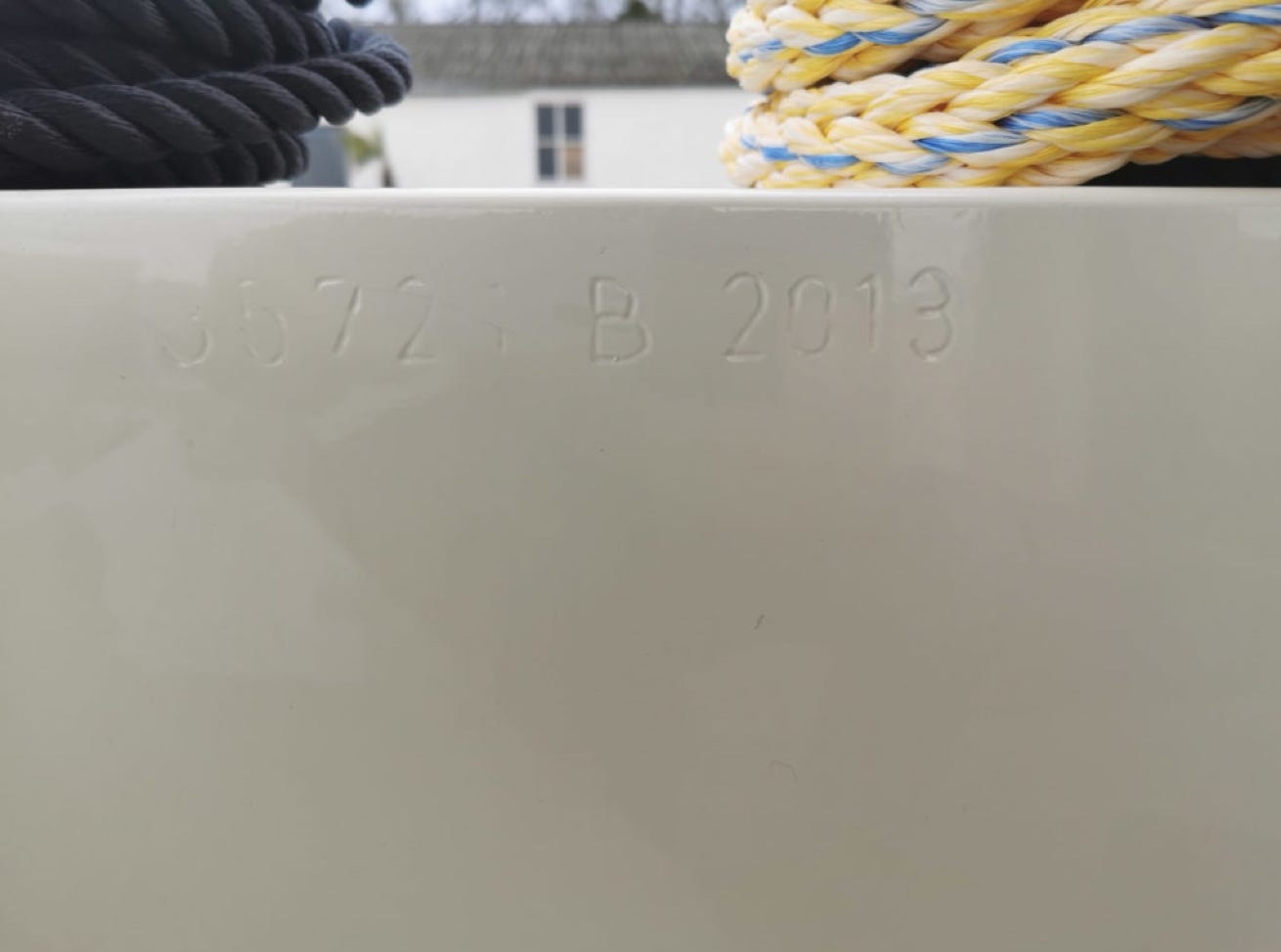

When Kees Cornelissen Shipyards International sold us the hull, it did not belong to KCSI at all. Rather, the hull belonged to his "private" company International Yachtbuilders BV. However, since Kees Cornelissen Shipyards International apparently never paid for the hull to International Yachtbuilders BV, the latter now wants the ship back. Back from us, well understood. And the whole ship. As proof, Cornelissen provided a cadastral entry of our boat from 2013. He had told us that the Casco was from 2015 or so.

After some searching, we found a cadastral number from 2013 on the bollard case, which was not on it when we inspected the boat in 2018 and 2019.

August 2020 – now you see it

September 2019 – now you don’t

We could have this order of arrest lifted by means of summary proceedings, but we decided to save the court the work and ourselves the costs and wait for the main trial, which had been scheduled for January 15, 2021. We can sail with the CaRo, but we are not allowed to leave the Netherlands with the boat.

. . .but the second prank follows immediately, to stay with Wilhelm Busch:

After Cornelissen found a buyer for our Adnobis in May 2020, we agreed to a sale. In return, the purchase sum was to be deposited in his lawyer's client money account. After all, we spent more than 200'000 euros to fix all the defects, which we would like to get back from Kees Cornelissen.

So a corresponding agreement was drawn up with the help of both lawyers. The amount would not cover the expenses by far, but it would at least be a damage limitation for us.

Shortly after signing, Cornelissen wanted to have this agreement annulled by court order on the grounds that he had been "put under pressure by us".

He did not succeed in the first instance. The judge ruled in a summary judgment that the funds had to remain in the account until judgment, as stipulated in the agreement.

Kees Cornelissen then went to court against himself with his company Euroship Jachtbouw BV against Kees Cornelissen Shipyards International BV.

All court proceedings always take place before the same court in Arnhem.

Euroship Jachtbouw sued Kees Cornelissen Shipyards International because KCSI apparently owed Euroship Jachtbouw money.

Since KCSI "simply did not" appear in court in this summary proceeding, the decision was automatically in favor of the plaintiff, Euroship Jachtbouw. And because Kees Cornelissen Shipyards International, as already established, has no assets in the company other than our deposit amount, Euroship Jachtbouw automatically received the right to payment of that very amount.

And we had actually believed that Cornelissen or at least his lawyer, Gert Jongeneel, would stick to an agreement set up and signed by both sides.

If our lawyer Joris Klompé was not as quick as he is, the money would probably have been paid out to Euroship Jachtbouw. We were just able to prevent this and also in this case the court will judge after the main trial on January 15, 2021.

Incidentally, Fritz Hommersom, the lawyer for the other party, resigned from all Cornelissen mandates sometime in early 2020. In his place, Gert Jongeneel of Jongeneel Advokaten now represents Kees Cornelissen and his companies. The ship expert Paul de Roock has also left. Today, an Albert van Zaltbommel of AyeAye Yachtxpertise writes Cornelissen's reports.

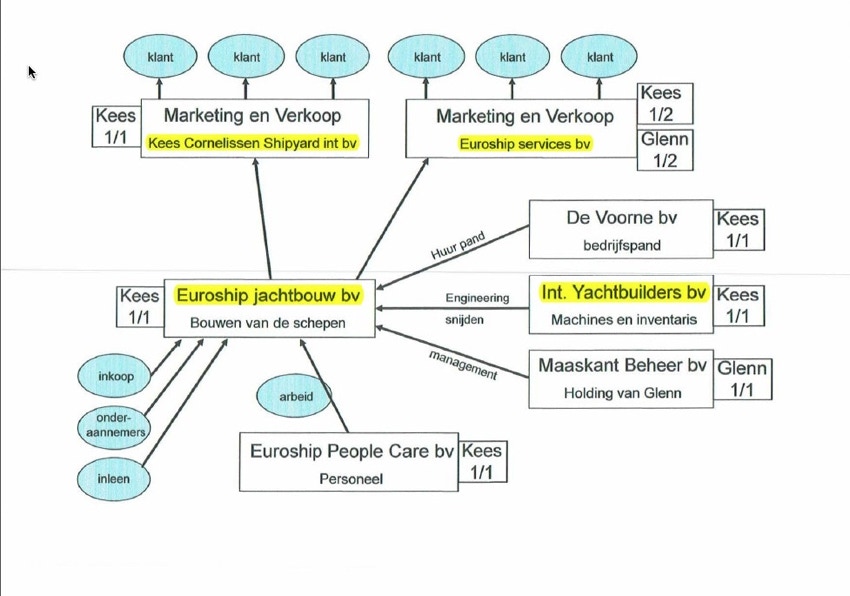

The conglomerate. Except Euroship Services (50%) all companies are 100% owned by Kees Cornelissen. The remaining 50% of Euroship Services is owned by Glenn Cornelissen, Kees' son.

The court proceedings of January 15, 2021, proceeded swiftly. We had the impression that the judge had carefully read through the court files, which comprised several folders.

The amount of paper that the other party produces is on a scale that makes you lose all track of it. At least, that's how we feel sometimes. It's good that Joris Klompé always keeps a cool head.

We'll wait and see for now. We can expect a first verdict in March 2021. However, it is possible that witnesses will still be heard or experts will visit the ship and the verdict will still be some time in coming.

Addendum to the water in the bilge:

After the end of the sailing season 2020, we decided to take the boat to Kees Cornelissen Shipyards resp. Euroship Services for repair because of all the water in the bilge. We never know exactly which company is in front of us, because we always have to deal with Kees or Glenn Cornelissen anyway. If indeed a leaking PVC water tank is the cause, the whole guest cabin would have to be disassembled to replace it. This would have cost several thousand Euros again and we could not and did not want to extend the risk of prepayment even further.

Roland went to the shipyard at the end of October 2020 and I went home with the Wuffs. Staying at the shipyard was not an option for me because of the atmosphere there.

Glenn Cornelissen looked at the damage and was of the opinion that the water was not coming from the PVC tank but had been in the bilge since it was first connected. At that time, the connection was not properly installed and about 500 liters of water leaked into it where the ballast was filled with it. Why had no one told us this?

In addition, we had not cleaned the filter in the shower water collection tank, which was mounted invisibly and inaccessibly under the floor planks. Water had also run into the bilge. Why wasn't that in the manual?

Last but not least, outside water was running back into the ship via the bilge pump. The cause would be that the installed check valve did not work.

Roland berthed with the Caro in Heerewaarden for a month. During this time, one of the windows also suffered a stress crack.